IZINDABA YENKAMPANI

《 EMUVA UHLU

Ungayikhetha kanjani imigoqo yokushaya efanele ye-horizontal shaft impactor?

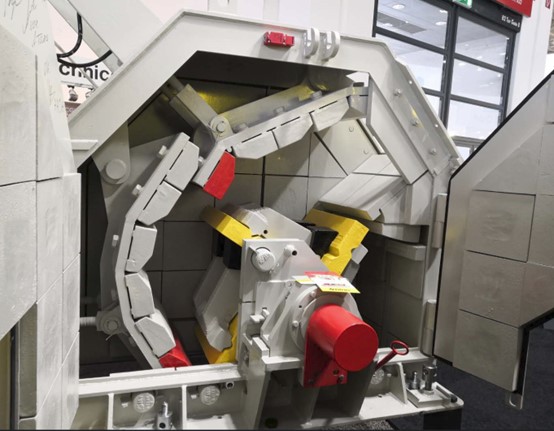

I-Horizontal Shaft Impactor (HSI) iwuhlobo lwemishini esindayo esebenza ukuchoboza amatshe, amatshe, ukhonkolo, ama-asphalt noma ezinye izinto ezidinga ukuncishiswa usayizi ukuze kulungiswe inqubo elandelayo enkwalini, ezimayini, zikasimende, embonini yezokwakha.

I-HSI impact crusher ikakhulukazi iqukethe injini, irotha, amaphinifa, izindlu ze- impactor kanye nezinsimbi zokushaywa. Isimiso sokusebenza se-impactor ukuthi i-motor ishayela i-rotor ebekwe ngokuvundlile kanye nama-blow bars afakwe ku-rotor ezungeza ngesivinini esikhulu kakhulu. Izinto eziphakelayo ezivela endaweni evulekile yokungena ye- impactor zishaywa ama-blow bar abheke kumapuleti omthelela afakwe kumaphinifa futhi abuyele emuva. Izinto ziyaphihlizwa futhi usayizi uncishiswe phakathi nale nqubo futhi zikhishwe endaweni yokuphuma kwe-impactor.

I-Blow bar iwukhiye nengxenye enkulu yokugqokwa kwabathintekayo. Njengoba i-rotor igijima ngesivinini esikhulu, imigoqo yokushaywa imelana nokushaqeka okukhulu kanye nokuhuzuka kwezinto ezichotshoziwe. Imishayo yokushaywa yizingxenye zokugqoka ezishintshwa kaningi futhi ziyingxenye enkulu yezindleko zokusebenza ze-impactor. Ukwenza ama-blow bar asebenze isikhathi eside kubaluleke kakhulu ukuze kugcinwe isikhathi sokusebenza kwe- impactor futhi kubiza kahle.

Noma yikuphi ukwehluleka ngezinsimbi zokushaywa kubiza ukulahleka okuphezulu ngesikhathi kanye nemali. I-blow bar enhle akufanele ihlale isikhathi eside ngangokunokwenzeka kodwa futhi isebenza ngokuphepha ngaphandle kokuphuka. Lokho kusho ukuthi ibha yokushaywa kufanele ibe nokumelana okuhle kokugqoka kanye nokumelana okwanele komthelela ngesikhathi esifanayo. Indlela yokwenza imigoqo yokuqhuma ihlale isikhathi eside? Impendulo isezintweni ezenziwe ngemigoqo yokuqhuma kanye nesisekelo lapho yenziwa khona.

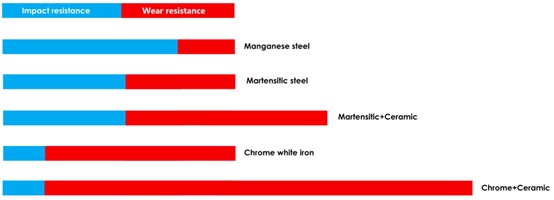

Izicelo zokuchotshozwa zihlala zihlukahlukene ngenxa yemvelo ehlukene nobukhulu obuhlukene bezinto ezichotshoziwe. Ukuze kube nokusebenza okuhle kakhulu ezinhlelweni ezihlukene, imigoqo yokushaywa ivamise ukwenziwa ekulandeleni izinto ezisetshenziswayo ukuze zibe nemvelo ehlukene mayelana nokuguga kanye nokumelana nomthelela.

Insimbi ye-Manganese

Insimbi yeManganese iwuhlobo lwensimbi ye-austenitic ene-Manganese engaba ngu-13% noma engu-18%. Ibonakala ngokumelana nomthelela omuhle kakhulu kodwa ukumelana nokugqokwa okuphansi. Insimbi yeManganese iyinketho yokuqala yamabha okushaya asetshenziswa kuma-crusher ayisisekelo noma esibili anosayizi omkhulu wokuphakelayo, ngokuvamile ngaphezu kwe-Dia. 800mm, noma izinhlelo zokusebenza ezinokuqukethwe okuphezulu kwezinto ezinganqamuki zingena kubathonya. Ukusetshenziswa okujwayelekile kwezigxobo zokushaywa kwe-manganese ukuchoboza ama-limestone ezitshalweni zenkwali zezitshalo zikasimende.

Insimbi ye-Manganese enamakholomu e-Titanium Carbide (TIC) efakiwe

Ngenxa yemvelo yokumelana nokugqokwa okuphansi kwensimbi ye-manganese, amakholomu e-Titanium Carbide (TIC) kwesinye isikhathi afakwa ebusweni obugqokile bensimbi yensimbi ye-manganese ukuze kwandiswe ukusebenza kwawo okugugile. Ngokufakwa kwe-TIC, impilo yesevisi yezinsimbi zokushaywa kwe-manganese ingase ikhuphuke ifike ku-60% kodwa izindleko zamabha wokushaya ziphezulu.

Insimbi ye-martensitic alloy

Insimbi ye-Martensitic uhlobo lwensimbi ye-alloy ene-Molybdenum, i-Nickel nezinye izithako ze-alloy ekuqanjweni kwayo. Ifakwe ngokusebenza kangcono kunensimbi ye-manganese kodwa ukusebenza komthelela kusengozini. Lolu hlobo luvumela imigoqo yokuqhuma kwe-martensitic ukuthi ifinyelele impilo engcono yokuguga ezinhlelweni zokusebenza lapho usayizi wokuphakelayo umncane noma okuqukethwe okuncane kwezinto ezinganqamuki ezingcolile. Ukusetshenziswa okujwayelekile kwamabha ensimbi ye-martensitic asetshenziswa kuma- impact aphinda agaywa amakhonkrithi anokuqukethwe kwama-rebar.

Insimbi ye-martensitic alloy ene-ceramic ifakiwe

Ukuze uthole impilo ende yokuguga yamabha ensimbi ye-martensitic, ama-grits e-ceramic yezimboni angafakwa ku-matrix yensimbi ye-martensitic yezindawo ezigugile. Ngenxa yokugqoka okuhle kakhulu kwezitsha zobumba, amabha ensimbi ye-martensitic angaba nempilo yokuguga ende engu-100%. Kodwa-ke, izindleko zemishayo yokushaywa zingaba ngu-50% zikhuphuke nge-ceramic efakiwe.

Insimbi emhlophe ye-Chrome

Insimbi emhlophe ye-Chrome inokuqukethwe okuphezulu kwekhabhoni ne-chromium kunensimbi ye-manganese nensimbi ye-martensitic, enikeza imigoqo yensimbi emhlophe e-chrome esebenza kahle kakhulu kodwa kakhulu.ukumelana nomthelela ophansi. I-Chrome emhlophe enokuqukethwe okungaba ngu-20% kwe-chromium ngokuvamile ibizwa ngokuthi i-chrome emaphakathi futhi cishe u-25% ibizwa nge-chrome ephezulu. Ama-Blow bars enziwe ngensimbi emhlophe ye-chrome ayinketho yokuqala yokuthi abathintekayo bachoboze amatshe abrasive kuma-crushers esibili noma aphezulu. Usayizi wokuphakela kwamadwala ku-impactor kumele ulawulwe ngokuqinile, ngokuvamile ngaphansi kwe-dia. 300mm, nanoma yiziphi izinto ezinganqamuki noma insimbi AYIVUMELEKILE ekuphakeleni. Uhlelo lokusebenza olujwayelekile lwezinsimbi zensimbi ezimhlophe ze-chrome lusetshenziselwa ukuchoboza amatshe emvelo noma ama-granite kuma-aggregate noma izitshalo zokwenza isihlabathi.

Insimbi emhlophe ye-Chrome efakwe nge-ceramic

Ukuze uthole futhi impilo ende yokuguga yamabha ensimbi e-chrome emhlophe, ama-ceramic grits nawo afakwa ezindaweni ezigugile. Impilo yokugqokwa kwama-blow bar e-chrome ingase inyuke ngo-100% kodwa izindleko nazo zikhuphuke ngo-50%. Ngaphezu kwalokho, i-Sunwill inezinsimbi ezikhethekile zebanga le-chrome ceramic grade ebangeni le-C650, elikwazi ukuzuza kufikela ku-170% ekukhuleni kokugqokwa kwezinhlelo zokusebenza zokuchoboza ezilimazayo zesibili noma zemfundo ephakeme.

Wonke ama-blow bars ayenziwe ekuqaleni kuma-Foundries. I-foundry enhle ngeke inikeze kuphela ikhwalithi enhle nethembekile ye-blow bar, kodwa futhi ikwazi ukunikeza izixazululo eziguquguqukayo nezintsha zezinhlelo zokusebenza ezithile ngesisekelo se-metallurgical.

I-Sunwill Machinery iyisizinda esinesipiliyoni seminyaka engaphezu kwe-15 ekukhiqizeni nasekusezweni imigoqo yokushaywa. I-Sunwill Machinery iyakwazi ukuhlinzeka ngazo zonke izinto ezingenhla ezifanela izinhlelo zokusebenza ezihlukene, futhi ochwepheshe be-metallurgist nonjiniyela bayakwazi ukwenza imigoqo yokuqhuma ifanele izinhlelo zokusebenza ezithile zekhasimende.

Sicela uvakashele i-Sunwill Machinery kuwww.sunwillmachinery.comnoma uthumele i-imeyili kuinfo@sunwillmachinery.comuma unemibuzo mayelana nemishayo yokushaywa kwabathintekayo noma udinga isisombululo esithile sesayithi. Siyajabula ukusiza noma nini.

Ezinye izihloko ezimayelana ne-Sunwill Blow Bar

Ingxenye 1:Isiqondiso sokukhetha amabha kanye nohlu lwemikhiqizo ye-Impactor

Ingxenye 2:Ungayenza kanjani ibha yokushaywa okuhle

Ingxenye 3:Izixazululo ezifanelekile zokugqokwa kwama-crusher omthelela