IZINDABA YENKAMPANI

《 EMUVA UHLU

Kanjani futhi kangakanani i-ceramic blow blow bar ikhulisa impilo yayo yokugqoka?

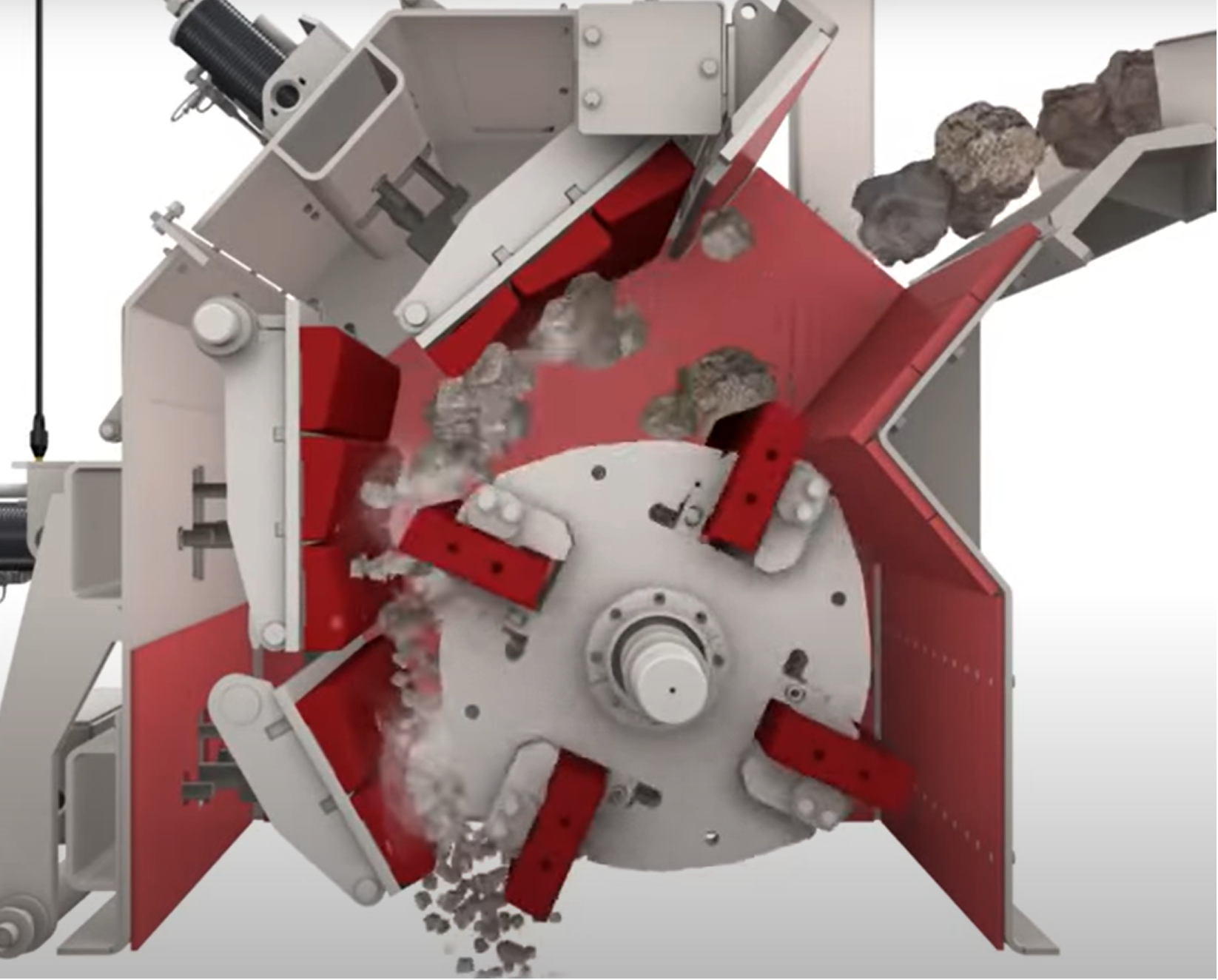

Ibha yokuvuthela noma ibha yokuphuka isando esifakwe ku-HSI - I-Horizontal Shaft Impactor esebenza ukuphula amatshe, amatshe, ukhonkolo noma ezinye izinto ezidinga ukuncishiswa usayizi. Isimiso sokusebenza silula. I-rotor emile evundlile ku-impactor ishayelwa injini ukuze ijikeleze ngesivinini esikhulu kakhulu. Amabha avuthelayo afakwe mpo noma acishwe ku-rotor ayazungezisa nawo. Lapho amatshe noma amatshe efakwa ku-impactor, ishaywa imigoqo yokuqhuma ejikelezayo emuva naphambili futhi iphihlizwe ibe yizicucu ezincane.

Kule nqubo yokuchotshozwa, imigoqo yokuqhuma isetshenziswa ukuhuzuka emadwaleni nawo anamandla okuthonya ngesivinini esikhulu. Ama-blower bamba ngokushesha futhi adinga ukushintshwa njalo. Ukushintshwa kwama-blow bar kubiza kakhulu ngokwezindleko ezisele, isikhathi esiphansi kanye nomsebenzi. futhi ilethe ingozi engaba khona yokulimala kubasebenzi ngesikhathi sokushintshwa. Ngakho-ke, imigoqo yokushaya ehlala isikhathi eside ifunwa kakhulu ngabasebenza nge-crusher.

Kule nqubo yokuchotshozwa, imigoqo yokuqhuma isetshenziswa ukuhuzuka emadwaleni nawo anamandla okuthonya ngesivinini esikhulu. Ama-blower bamba ngokushesha futhi adinga ukushintshwa njalo. Ukushintshwa kwama-blow bar kubiza kakhulu ngokwezindleko ezisele, isikhathi esiphansi kanye nomsebenzi. futhi ilethe ingozi engaba khona yokulimala kubasebenzi ngesikhathi sokushintshwa. Ngakho-ke, imigoqo yokushaya ehlala isikhathi eside ifunwa kakhulu ngabasebenza nge-crusher.

Amabha okushaya ngokuvamile enziwa ngezinsimbi ze-alloy ezihlanganisa insimbi ye-manganese, insimbi ye-martensitic noma insimbi ye-chrome. Impilo yokugqoka ye-blow bars incike ebukhuni bensimbi ye-alloy eyenziwe. Ngenxa yomkhawulo wempahla eyimishini yensimbi eyingxubevange, kunzima kakhulu ukuyenza ibe nzima kakhulu kodwa ayiphuli lapho uthola amandla okubamba okwamanje ngezindleko ezithwalekayo.

Kulesi simo, ibha yokuvuthela ye-ceramic yasungulwa onjiniyela futhi ifakazelwe njengesixazululo esisebenza kahle kakhulu sokwandisa impilo yokugqoka yama-blow bar. Ibha ye-Ceramic blow nayo yenziwe nge-alloy steel casting kodwa enobulukhuni obuphezulu be-ceramics yezimboni eshunyekiwe. I-ceramics ekuqaleni yenziwa ngezinhlayiya ezincane futhi zicutshungulwa ku-cube yekhekhe lezinyosi. Ikhekheba lezinyosi le-Ceramic lifakwa ezindaweni zokugqoka futhi lihlanganiswe noketshezi lwensimbi lapho i-blow bar iphonswa ku-Foundry. Ngemuva kokuthi ukubunjwa kuqiniswe, ama-ceramics enza isigaba esinzima kakhulu kubha yokushaywa. Izingxenye ze-ceramic eziqinile zinikeza ukusebenza okuhle kakhulu kokugqokwa futhi zikhulisa impilo yokuguga lapho i-blow bar isebenzela ukuchotshozwa kwe-impactor, kodwa ayibeki engcupheni ikhono le-blow bar yonke ukuze imelane namandla omthelela.

Amabha e-Ceramic blow ngokuvamile angafinyelela ubude bempilo obuphindwe kabili be-mono-alloy blow bar evamile. Kwezinye izimo impilo yokugqoka ingakhuphuka ngo-200%. Kodwa-ke, njengoba i-ceramic ikhulisa kuphela ukusebenza kokugqokwa kwe-blow bar kodwa ingenzi lutho ekusebenzeni okumelana nomthelela, lapho ukhetha amabha wokushaya izimo zokuchoboza zisadingeka ukuthi zicatshangelwe. Isibonelo, lapho kubhidlizwa amakhonkrithi esakhiwo ngosayizi omkhulu, imigoqo yokushaywa ngokuvamile yenziwa ngensimbi ye-martensitic, Kulesi simo, ibha yensimbi ye-martensitic ene-ceramic nayo iwukuphela kwenketho yokuphila isikhathi eside.

Ngaphandle kwesikhathi eside sokuguga, imigoqo yokushaywa ye-ceramic iphinde isize ekwandiseni umkhiqizo ngehora le-crusher enomthelela ngoba indawo eqinile nemiphetho ecijile ye-blow bar inyusa ukusebenza kahle kokuchotshozwa. Izinsimbi zobumba zobumba ngokuvamile zikhiqiza u-5% -10% ngaphezulu ngehora ngalinye kunemigoqo yokuvuthela ye-mono-alloy.

Imvamisa, amabha okushaywa e-ceramic anconyelwe ukuchotshozwa kwesibili kanye nesigaba semfundo ephakeme noma ukugaywa kabusha kokhonkolo kanye netiyela. Ama-blow bars e-Cramic ye-Chrome ngokuvamile ayisixazululo esihle sesibili nesiphakeme sokuchotshozwa kanye nezinsimbi ze-martensitic ceramic zokugaya kabusha ukhonkolo. Nakuba i-ceramic ingesona isixazululo se-manganese steel blow bars yokuchotshozwa okuyinhloko ngamatshe amakhulu kakhulu agaywe.

Uma kuqhathaniswa ne-mono-alloy blow bar, ibha yokuvuthela ye-ceramic iyinselele enkulu okufanele yenziwe. Kudinga ukuthi isizinda sibe nobuchwepheshe bokulingisa obuthuthuke kakhulu kanye nemishini, ukuphathwa kokukhiqiza okusezingeni eliphezulu kanye namazinga okulawula ikhwalithi. Zimbalwa kuphela izisekelo ezikwazi ukwenza imigoqo yokushaywa kwe-ceramic ngokuthembekile emhlabeni. I-Sunwill Machinery iphakathi kwabaphambili ngesipiliyoni sabo seminyaka engaphezu kwe-10 sokukhiqiza ama-ceramic blow bar. Buka ividiyo ye-Foundry ukuze ubone okwengeziwehttps://youtu.be/d8aqjsawwj0