IINDABA zeNKAMPANI

《 ULUHLU NGEMVA

Unokukhetha njani imivalo yokuvuthela ekunene kwimpembelelo ye-shaft ethe tye?

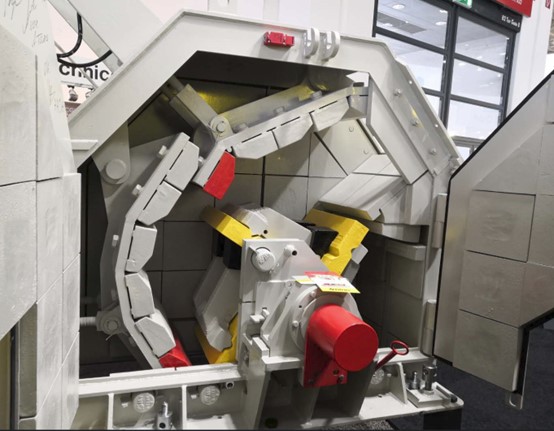

I-Horizontal Shaft Impactor (HSI) luhlobo lomatshini onzima osebenza ukutyumza amatye, amatye, iikhonkrithi, ii-asphalts okanye ezinye izinto ezifuna ukunciphisa ubungakanani ukulungiselela inkqubo elandelayo kwi-quarry, imigodi, i-samente, ishishini lokwakha.

I-HSI ifuthe isityumzi ikakhulu iqulathe injini, rotor, ifaskoti, impembelelo yezindlu kunye nemivalo yokuvuthela. Umgaqo osebenzayo we-impact yi-motor eqhuba i-rotor ephakanyisiweyo ngokuthe tye kunye nemivalo yokuvuthela efakwe kwi-rotor ejikelezayo ngesantya esiphezulu kakhulu. Izinto ezondlayo ukusuka kwi-inlet evulekileyo ye-implant ibethwe yimivalo yokuvuthela ukuya kwiipleyiti zempembelelo ezifakwe kwiifaskoti kunye nokubuyela umva. Izinto ziyaphulwa kwaye ubungakanani buncitshisiwe ngexesha le nkqubo kwaye zikhutshwe kwi-outlet of impactor.

Ibha yokuvuthela yeyona nto ibalulekileyo kunye neyona nxalenye inkulu yokunxiba kwiimpembelelo. Njengoko i-rotor ibaleka ngesantya esiphezulu, imivalo yokuvuthela imelana nomothuko omkhulu kunye ne-abrasion ye-abrasion evela kwizinto ezityumkileyo. Imivalo yeBlow zezona nxalenye zokunxiba ezitshintshwa rhoqo kwaye i-akhawunti yenxalenye enkulu yeendleko zokusebenza ze-impaor. Ukwenza imivalo yokuvuthela isebenze ixesha elide kubaluleke kakhulu ukugcina ixesha elisebenzayo kunye neendleko ezifanelekileyo.

Nakuphi na ukungaphumeleli kunye nemivalo yokuvuthela kubiza ilahleko ephezulu ngexesha kunye nemali. Ibha yokuvuthela efanelekileyo akufanele ihlale ixesha elide kangangoko kunokwenzeka kodwa iphinde isebenze ngokukhuselekileyo ngaphandle kokuphuka. Oko kuthetha ukuba ibha yokuvuthela kufuneka ibe nokuchasana okulungileyo kokunxiba kunye nokuchasana okwaneleyo kwimpembelelo ngexesha elinye. Indlela yokwenza imivalo yokuvuthela ihlale ixesha elide? Impendulo ikwizixhobo ezivuthela imivalo kunye nesiseko apho yenziwa khona.

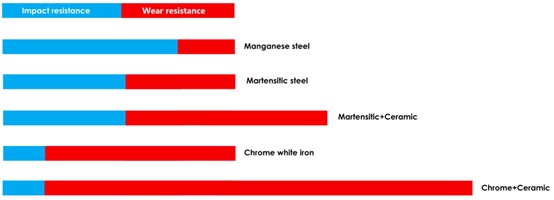

Izicelo zokutyumza zihlala zihlukeneyo ngenxa yendalo eyahlukeneyo kunye nobukhulu obuhlukeneyo bezinto ezityumkileyo. Ukuze ube neyona ntsebenzo ilungileyo kwizicelo ezahlukeneyo, imivalo yokuvuthela iqhele ukwenziwa ngokulandela imathiriyeli ukuba ibe nendalo eyahlukileyo ngokwendlela yokunxiba kunye nokuchasa impembelelo.

Intsimbi yeManganese

Intsimbi yeManganese luhlobo lwentsimbi ye-austenitic ejikeleze i-13% okanye i-18% yomxholo weManganese. Ibonakaliswe ngempembelelo entle kakhulu yokuchasa kodwa ukumelana nokunxiba okuphantsi. Intsimbi yeManganese lukhetho lokuqala lweebhari zokuvuthela ezisetyenziswa kwizityuli eziziiprayimari okanye ezesibini ezinobungakanani besondlo esikhulu, ngokwesiqhelo ngaphezulu kweDia. I-800mm, okanye izicelo ezinomxholo ophezulu wezinto ezingenakuphulwa zingena kwiimpembelelo. Ukusetyenziswa okuqhelekileyo kweentsimbi zokuvuthela zemanganese kukutyumza amatye ekalika kwizityalo zekwari zezityalo zesamente.

Intsimbi yeManganese eneentsika zeTitanium Carbide (TIC) zifakiwe

Ngenxa yobume bokunganyangeki okuphantsi kwentsimbi yemanganese, iikholamu zeTitanium Carbide (TIC) ngamanye amaxesha zifakwa kubuso obunxibileyo bentsimbi yentsimbi yemanganese imivalo yokunyusa ukusebenza kwayo. Ngofakelo lwe-TIC, ubomi benkonzo yeentsimbi zokuvuthela imanganese bunokonyuka ukuya kuthi ga kwi-60% kodwa ixabiso leentsimbi zokuvuthela liphezulu.

Intsimbi yentsimbi ye-martensitic

Intsimbi ye-Martensitic luhlobo lwentsimbi ye-alloy kunye ne-Molybdenum, i-Nickel kunye nezinye izithako ze-alloy kwiingoma zayo. Ibonakaliswe ngokusebenza okungcono kokunxiba kunentsimbi yemanganese kodwa ukusebenza kwempembelelo kusengozini. Olu hlobo luvumela imivalo ye-martensitic ukuba ifezekise ubomi obungcono bokunxiba kwizicelo apho ubungakanani bokutya buncinci okanye umxholo omncinci wezinto ezingonakali zingcolisekileyo. Ukusetyenziswa okuqhelekileyo kweentsimbi zentsimbi ye-martensitic zisetyenziswa kwiimpembelelo zokuhlaziya iikhonkrithi kunye nomxholo we-rebars.

Intsimbi ye-martensitic alloy ene-ceramic ifakiwe

Ukufumana ubomi obude bentsimbi yeentsimbi zemartensitic, iigrits zeeramic kwimizi-mveliso zinokufakwa kwimatrix yentsimbi yemartensitic yeendawo zokunxiba. Ngombulelo wokusebenza okugqwesileyo kweeseramikhi, iintsimbi zentsimbi ye-martensitic zinokuba ne-100% yobomi obude bokunxiba. Nangona kunjalo, ixabiso leentsimbi zokuvuthela malunga ne-50% linyukile kunye ne-ceramic efakiweyo.

Intsimbi emhlophe yeChrome

Intsimbi emhlophe yeChrome inomxholo ophezulu wekhabhoni kunye nechromium kunentsimbi yemanganese kunye nentsimbi yemartensitic, enika imivalo yentsimbi emhlophe yechrome esebenza ngokugqwesileyo kodwa kakhulu.ukumelana nempembelelo ephantsi. I-Chrome emhlophe emalunga ne-20% yomxholo wechromium ikholisa ukubizwa ngokuba yi-chrome ephakathi kwaye malunga ne-25% ibizwa ngokuba yi-high chrome. Imivalo yokuvuthela eyenziwe ngentsimbi emhlophe ye-chrome lukhetho lokuqala lweempembelelo ezityumzayo amatye arhabaxa kakhulu kwizityuli zesibini okanye eziphakamileyo. Ubungakanani amatye feed kwi impactor kufuneka ilawulwe ngokungqongqo, ngokuqhelekileyo ngaphantsi kwe dia. I-300mm, kunye naziphi na izinto ezingonakaliyo okanye i-iron tramp AYIVUMELEKANGA ekutyiseni. Ukusetyenziswa okuqhelekileyo kweentsimbi ezimhlophe zechrome zentsimbi zisetyenziselwa ukutyumza amatye endalo okanye iigranite kwii-aggregates okanye izityalo ezenza isanti.

Intsimbi emhlophe yeChrome eneceramic ifakiwe

Ukufumana kwakhona ubomi obude bentsimbi emhlophe yekhrom, iigrits ze-ceramic zikwafakwa kwiindawo zokunxiba. Ubomi bokunxiba beeblowu ze-chrome bunokonyuka nge-100% kodwa ixabiso likwamalunga nama-50%. Ngaphaya koko, i-Sunwill inemigangatho ekhethekileyo yekhromium yokuvuthela imivalo kwibakala le-C650, ekwaziyo ukufikelela ukuya kuthi ga kwi-170% yokwanda kubomi bokunxiba kwi-abrasive kakhulu okanye kwizicelo ezityumzayo eziphakamileyo.

Yonke imivalo yokuvuthela yenziwe ekuqaleni kwiziseko. Isiseko esihle asiyi kubonelela kuphela ngomgangatho olungileyo kunye nothembekileyo wemivalo yokuvuthela, kodwa kwakhona ukwazi ukubonelela ngezisombululo eziguquguqukayo kunye nezintsha kwizicelo ezithile kwisiseko se-metallurgical.

I-Sunwill Machinery yindawo esisiseko enamava angaphezu kweminyaka eli-15 kwimveliso kunye nenkonzo yeebhari zokuvuthela. I-Sunwill Machinery iyakwazi ukubonelela ngazo zonke izixhobo ezingentla zilungele usetyenziso olwahlukileyo, ngokunjalo ii-metallurgists kunye neenjineli ziyayazi indlela yokwenza imivalo yokuvuthela ilungile kwizicelo ezithile zomthengi.

Nceda undwendwele i-Sunwill Machinery kuwww.sunwillmachinery.comokanye ulahle i-imeyileinfo@sunwillmachinery.comxa unemibuzo malunga nemivalo yokuvuthela kwiimpembelelo okanye ufuna isisombululo esithile sesayithi. Siyavuya ukuncedisa nangaliphi na ixesha.

Eminye imixholo malunga ne-Sunwill Blow Bar

Icandelo 1:Isikhokelo sokuvuthela iibar kunye noluhlu lweempawu ze-Impactor

Icandelo 2:Uyenza njani ibha yokuvuthela elungileyo

Icandelo 3:Izisombululo zokunxiba ezifanelekileyo kwizityuli zempembelelo