IINDABA zeNKAMPANI

《 ULUHLU NGEMVA

Njani kwaye kangakanani i-ceramic blowu bar inyusa ubomi bayo bokunxiba?

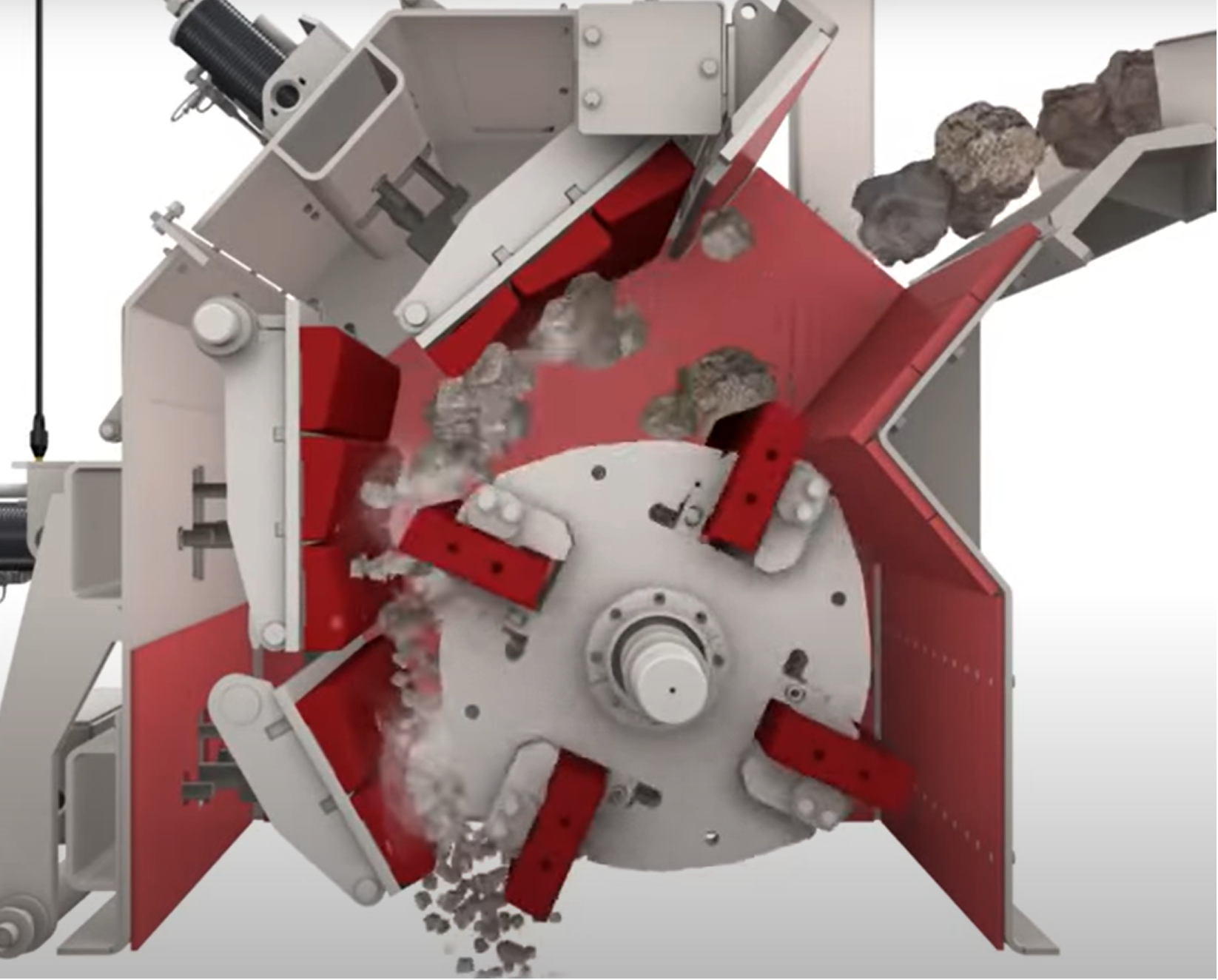

Ibha yokuvuthela okanye ibha yekhefu yihamile exhonywe kwi-HSI - I-Horizontal Shaft Impactor isebenze ukwaphula amatye, amatye, iikhonkrithi okanye ezinye izinto ezifuna ukucuthwa ubungakanani. Umgaqo wokusebenza ulula. I-rotor ebekwe ngokuthe tye kwi-impactor iqhutywa yi-motor ukujikeleza ngesantya esiphezulu kakhulu. Imivalo yokuvuthela efakwe ngokuthe nkqo okanye ebotshelelwe kwirotor iyajikeleza ngokunjalo. Xa amatye okanye amatye etyiswa kwi-impactor, ibethelwa yimivalo ejikelezayo ejikelezayo emva naphambili kwaye iqhekeke ibe ngamaqhekeza amancinci.

Kule nkqubo yokutyumza, imivalo yokuvuthela iphantsi kokukhonza i-abrasion evela ematyeni kwakhona amandla empembelelo enamandla kwisantya esiphezulu. Imivalo yokuvuthela inxiba ngokukhawuleza kwaye ifuna ukutshintshwa rhoqo. Ukutshintshwa kweebhari zokuvuthela kubiza kakhulu ngokweendleko ezisecaleni, ixesha eliphantsi kunye nomsebenzi. kunye nokuzisa umngcipheko wokwenzakala kubasebenzi ngexesha lenkqubo yokutshintshwa. Ke ngoko, imivalo yokuvuthela ehlala ixesha elide ifunwa ngamandla ngabaqhubi be-crusher.

Kule nkqubo yokutyumza, imivalo yokuvuthela iphantsi kokukhonza i-abrasion evela ematyeni kwakhona amandla empembelelo enamandla kwisantya esiphezulu. Imivalo yokuvuthela inxiba ngokukhawuleza kwaye ifuna ukutshintshwa rhoqo. Ukutshintshwa kweebhari zokuvuthela kubiza kakhulu ngokweendleko ezisecaleni, ixesha eliphantsi kunye nomsebenzi. kunye nokuzisa umngcipheko wokwenzakala kubasebenzi ngexesha lenkqubo yokutshintshwa. Ke ngoko, imivalo yokuvuthela ehlala ixesha elide ifunwa ngamandla ngabaqhubi be-crusher.

Imivalo yokuvuthela iqhele ukwenziwa ngeentsimbi zealloy kubandakanya intsimbi yemanganese, intsimbi yemartensitic okanye intsimbi yechrome. Ubomi bokugqoka bemivalo yokuvuthela buxhomekeke kubunzima bensimbi ye-alloy eyenziwe ngayo. Ngenxa yomda wepropathi yomatshini wentsimbi ye-alloy, kunzima kakhulu ukuyenza nzima kakhulu kodwa ayiphuli xa ifumana amandla empembelelo okwangoku ngexabiso elithwalekayo.

Kule meko, ibha yokuvuthela yeceramic yaqanjwa ziinjineli kwaye ingqinwe esona sisombululo sisebenzayo sokwandisa ubomi bokunxitywa kwemivalo yokuvuthela. Ibha yokuvuthela yeCeramic nayo yenziwe ngentsimbi yealloyi kodwa inobulukhuni obuphezulu beseramikhi zamashishini ezizinzisiweyo. I-ceramics yenziwe ekuqaleni kwiincinci ezincinci kwaye zicutshungulwe kwi-cube ye-honeycomb. I-honeycomb ye-Ceramic ibekwe kwiindawo zokunxiba kwaye idityaniswe kunye nolwelo lwesinyithi xa ibha yokuvuthela iphoswa kwi-Foundry. Emva kokuba i-casting iqinisiwe, i-ceramics yenza icandelo elinzima kakhulu kwi-blow bar. Amacandelo e-ceramic anzima abonelela ngokugqwesileyo kokunxiba kunye nokwandisa ubomi bokunxiba xa ibha yokuvuthela isebenza ngokutyumza kwi-impaor, kodwa ayibeki esichengeni ukukwazi kwebha yokuvuthela yonke ukumelana namandla empembelelo.

Imivalo yokuvuthela yeCeramic idla ngokufezekisa ubude bobomi obuphindwe kabini beebhari zokuvuthela eziqhelekileyo ze-mono-alloy. Kwezinye iimeko ubomi bokunxiba bunokunyuswa ngama-200%. Nangona kunjalo, njengoko i-ceramic inyusa kuphela ukusebenza kwebhari yokuvuthela kodwa ingenzi nto ekusebenzeni okuchasene nempembelelo, xa ukhetha imivalo yokuvuthela iimeko ezityumzayo zisafuneka ukuba zithathelwe ingqalelo. Ngokomzekelo, xa iikhonkrithi zesakhiwo ezidiliziweyo ngobukhulu obukhulu, imivalo yokuvuthela idla ngokwenziwa ngentsimbi ye-martensitic, Kule meko, ibha yentsimbi ye-martensitic ene-ceramic ikwayiyo kuphela inketho yokunxiba ixesha elide.

Ngaphandle kwexesha elide lokunxiba, imivalo yokuvuthela yeceramic ikwanceda ekonyuseni imveliso ngeyure yesityumzi ngenxa yokuba umphezulu orhabaxa kunye nemiphetho ebukhali yebha yokuvuthela nayo yonyusa ukusebenza kakuhle. Imivalo yokuvuthela yeCeramic idla ngokuvelisa i-5% -10% ngaphezulu kwiyure nganye kuneentsimbi zokuvuthela i-mono-alloy.

Ngokwesiqhelo imivalo yokuvuthela yeceramic iyacetyiswa kwisekondari nakwinqanaba lesithathu lokutyunyuzwa okanye ukurisayikilishwa kwekhonkrithi kunye ne-asphalt. Imivalo ye-ceramic ye-Chrome idla ngokuba sisisombululo esilungileyo sesekondari kunye nenqanaba eliphezulu kunye neebar ze-martensitic ze-ceramic zokuphinda zisetyenziswe kwikhonkrithi. Ngelixa i-ceramic ayisosisombululo sentsimbi ye-manganese yokuvuthela imivalo yokutyumza ilitye elikhulu kakhulu.

Xa kuthelekiswa nemivalo yokuvuthela ye-mono-alloy, ibha ye-ceramic blowu ngumngeni omkhulu wokwenziwa. Ifuna i-Foundry ukuba ibe nobuchwepheshe bokuphosa obuphezulu kunye nezixhobo, ulawulo lokuvelisa umgangatho ophezulu kunye nemigangatho yokulawula umgangatho. Zimbalwa iziseko ezikwaziyo ukwenza iibhari zeceramic ngokuthembekileyo kwihlabathi. Oomatshini be-Sunwill baphakathi kwabaphezulu kunye neminyaka engaphezu kwe-10 yamava okwenziwa kwee-ceramic blow bars. Bukela ividiyo ye-Foundry ukuze ubone ngakumbihttps://youtu.be/d8aqjsawwj0