COMPANY NEWS

《 BACK LIST

How and how much does ceramic blow bar increase its wear life?

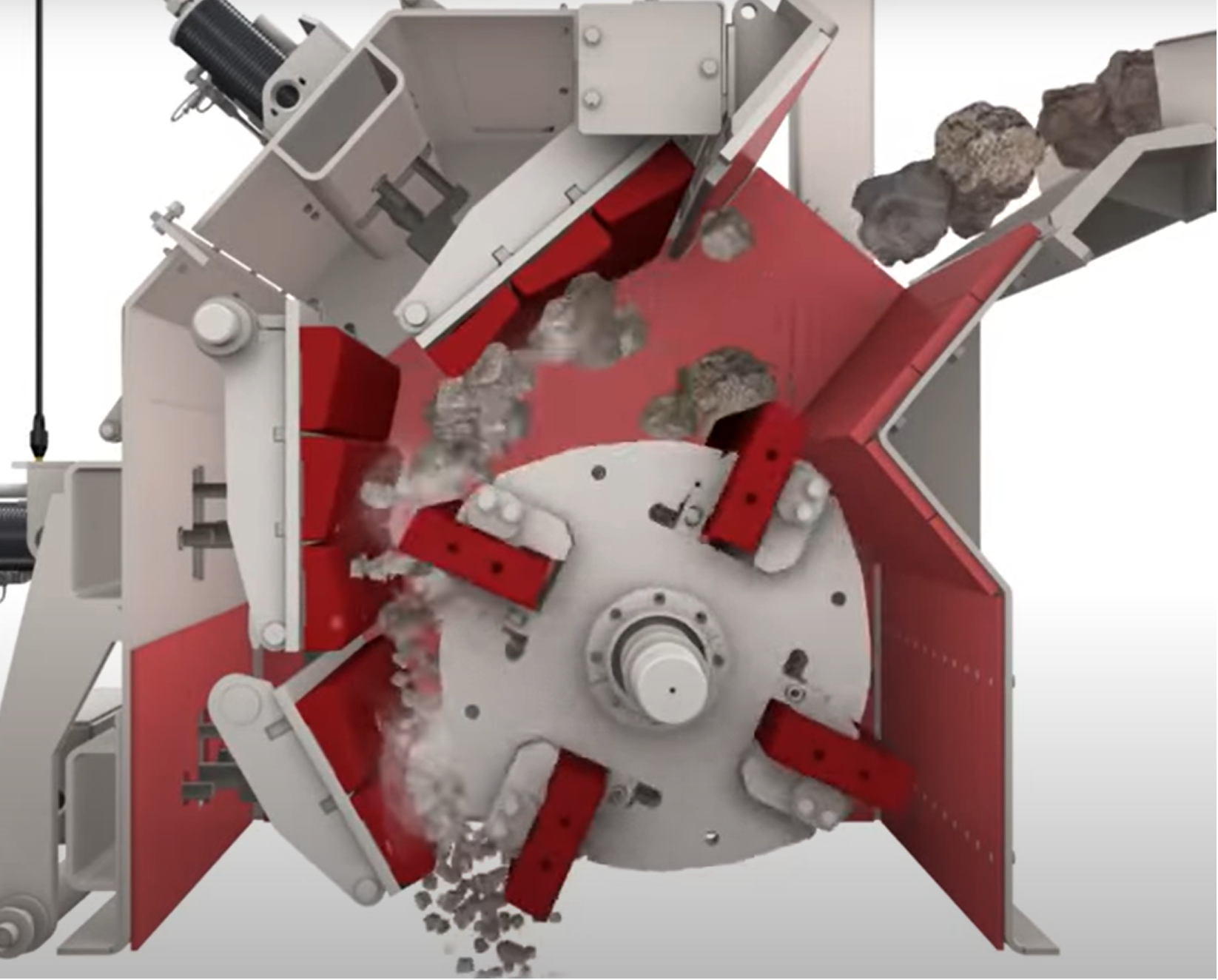

Blow bar or break bar is the hammer mounted on HSI – Horizontal Shaft Impactor functioned to break the rocks, stones, concretes or other stuff that need to be reduced size. The working principle is simple. The horizontally positioned rotor in impactor is driven by a motor to rotate at a very high speed. Blow bars that are vertically inserted or clamped in rotor rotate as well. When the rocks or stones fed into the impactor, it’s hit by the rotating blow bars back and forth and shattered into small pieces.

In this crushing process, blow bars are subjected to serve abrasion from the rocks also strong impact force at high speed. Blow bars wear quickly and need to be replaced frequently. The blow bars replacement is very costly in terms of spare cost, down time and labor. and also bring the potential injuring risk to workers during the process of replacement. Hence, the longer lasting blow bars are desperately wanted by the crusher operators.

In this crushing process, blow bars are subjected to serve abrasion from the rocks also strong impact force at high speed. Blow bars wear quickly and need to be replaced frequently. The blow bars replacement is very costly in terms of spare cost, down time and labor. and also bring the potential injuring risk to workers during the process of replacement. Hence, the longer lasting blow bars are desperately wanted by the crusher operators.

Blow bars are normally made of the alloy steels including manganese steel, martensitic steel or chrome steel. The wear life of blow bars depends on the hardness of alloy steel made of. Due to the limit of mechanical property of alloy steel, it is too difficult to make it very hard but doesn’t break when receive the impact force meanwhile at a bearable cost.

In this circumstance, ceramic blow bar is invented by engineers and has been proven the most efficient solution to increase wear life of blow bars. Ceramic blow bar is also made of alloy steel casting but with high hardness industrial ceramics embedded. The ceramics is originally made in tiny particles and processed to a honeycomb cube. Ceramic honeycomb is placed at the wearing areas and bonded with the metal fluid when the blow bar is cast in foundry. After the casting solidified, the ceramics forms a very hard section on blow bar. The hard ceramic sections provide excellent wear performance and increases wear life when blow bar works for crushing in impactor, but doesn’t compromise the ability of whole blow bar to withstand impact force.

Ceramic blow bars can usually achieve a doubled life span of the conventional mono-alloy blow bars. In some cases the wear life can be increased by 200%. However, as the ceramic only increases the wear performance of blow bar but doesn’t do anything to the impact-resistant performance, when select blow bars the crushing conditions is still necessary to be taken into consideration. For example, when crush demolished building concretes in large size, the blow bars are usually made of martensitic steel, In this condition, martensitic steel blow bar with ceramic is also the only option for longer wear life.

Besides the longer wear time, ceramic blow bars also help to increase the productivity per hour of impact crusher because the rougher surface and sharper edges of blow bar also increase the crushing efficiency. Ceramic blow bars usually produce 5%-10% more in every hour than the mono-alloy blow bars.

Normally ceramic blow bars are recommended for secondary and tertiary crushing or recycling concretes and asphalt. Chrome ceramic blow bars are usually a good solution for secondary and tertiary crushing and martensitic ceramic blow bars for recycling concrete. While ceramic is not a solution for manganese steel blow bars for primary crushing with very large stone crushed.

Compared with mono-alloy blow bars, ceramic blow bar is a big challenge to be manufactured. It requires the foundry to have more advanced casting technology and equipment, higher-level manufacturing management and quality control standards. Only a few foundries are capable of manufacturing the ceramic blow bars reliably in the world. Sunwill Machinery is among the top with their over 10 years of manufacturing experience of ceramic blow bars. Watch the video of foundry to see more https://youtu.be/d8aqjsawwj0